In the Middle: Finding the Right Stud Length

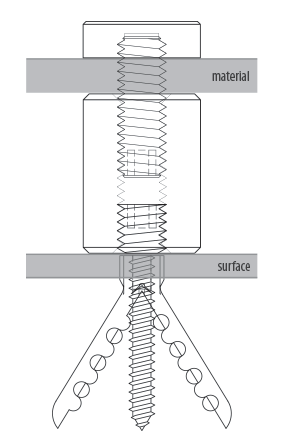

Studs are the hardware that holds a project together. They connect a cap to its barrel but, because you can’t see them once the project is finished, they are often a design afterthought. With a little background information, you can choose the correct stud or, if you prefer, call for a professional recommendation.

There are four things to consider when choosing a stud. You’ll need to know how deep your cap threads are, how far into the barrel you can screw the stud, how thick the material being mounted is and, finally, you’ll need to make sure your cap, barrel and stud are all threaded in the same size. If you’re going to mount glass, you may also want to account for added material thickness in the form of protective vinyl washers.

There are four things to consider when choosing a stud. You’ll need to know how deep your cap threads are, how far into the barrel you can screw the stud, how thick the material being mounted is and, finally, you’ll need to make sure your cap, barrel and stud are all threaded in the same size. If you’re going to mount glass, you may also want to account for added material thickness in the form of protective vinyl washers.

For example, let’s say you’re mounting a piece of 1/8-inch acrylic using an SO-9100 barrel and an SO-CAP9 cap. The cap’s thread depth is 1/4-inch. The barrel is tapped all the way through, but you also need to account for the anchor, which will take up some of that space. In this case, plan on inserting the stud 3/8-inch into the barrel. Finally, the acrylic being mounted is 1/8-inch thick, meaning you’ll want a stud with a total length of 3/4-inches and threaded in 5/16-18 – this is an HD-S18. Of course, specific requirements vary from project to project, but the concept remains the same and our Client Solutions Specialists are available to help.