In a Pinch: Suspend Heavier Designs Using Swaged Wire Assemblies

Many wire applications are held in place by a set screw, which pinches the wire against the assembly body. This simple method works great for lighter applications, but for a heavier project you’ll want something a little more robust.

Gyford EZ-wire components labeled “EZ-AH” are intended to suspend heavier designs and use a swage rather than a set screw to anchor the wire in place. Sometimes you can do this at home, other times it’s better to order your wire pre-swaged from our facility. This depends on the swage material and the weight you intend to hold with the wire.

Gyford EZ-wire components labeled “EZ-AH” are intended to suspend heavier designs and use a swage rather than a set screw to anchor the wire in place. Sometimes you can do this at home, other times it’s better to order your wire pre-swaged from our facility. This depends on the swage material and the weight you intend to hold with the wire.

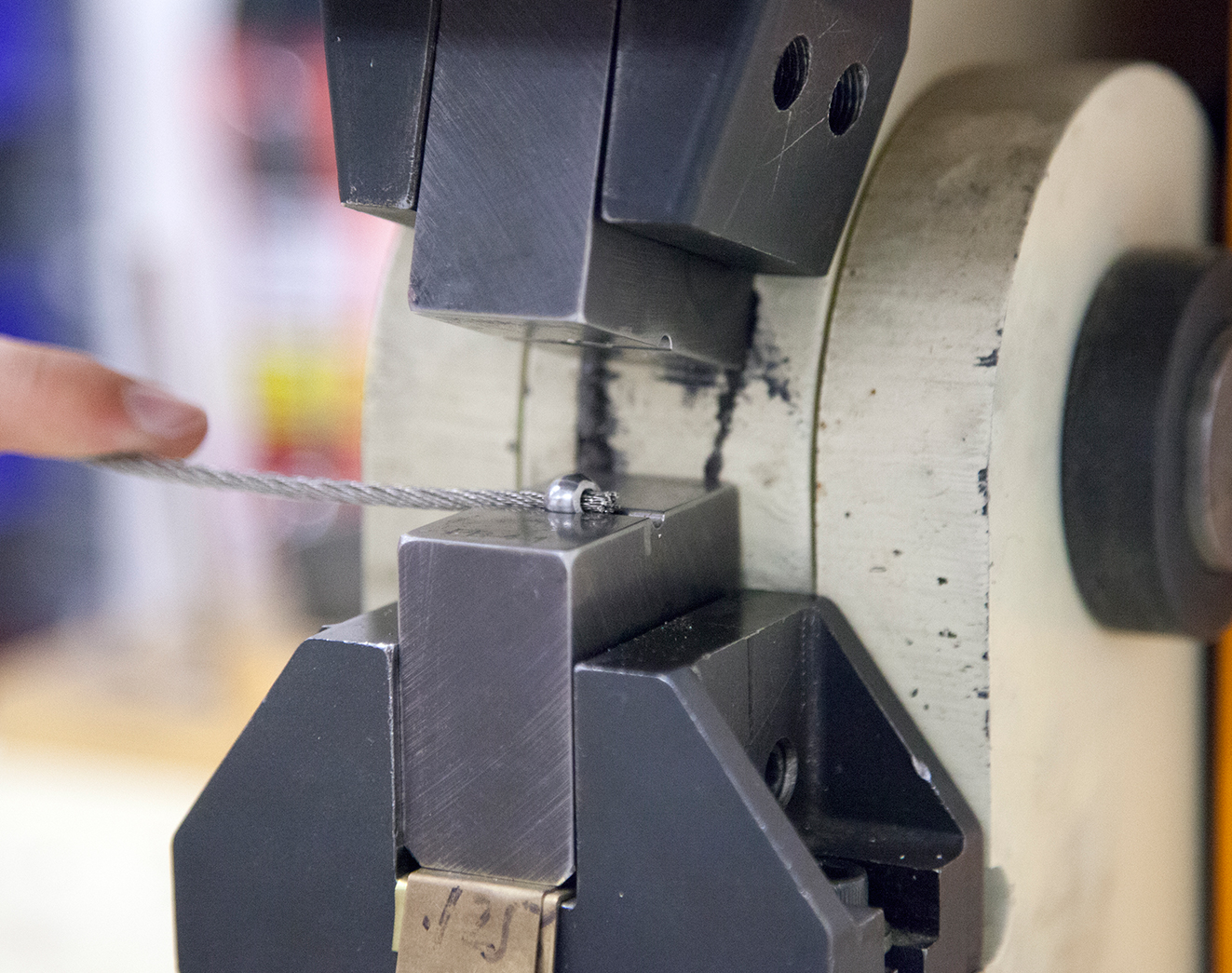

We swage to manufacturers’ exact specifications with a hydraulic press.

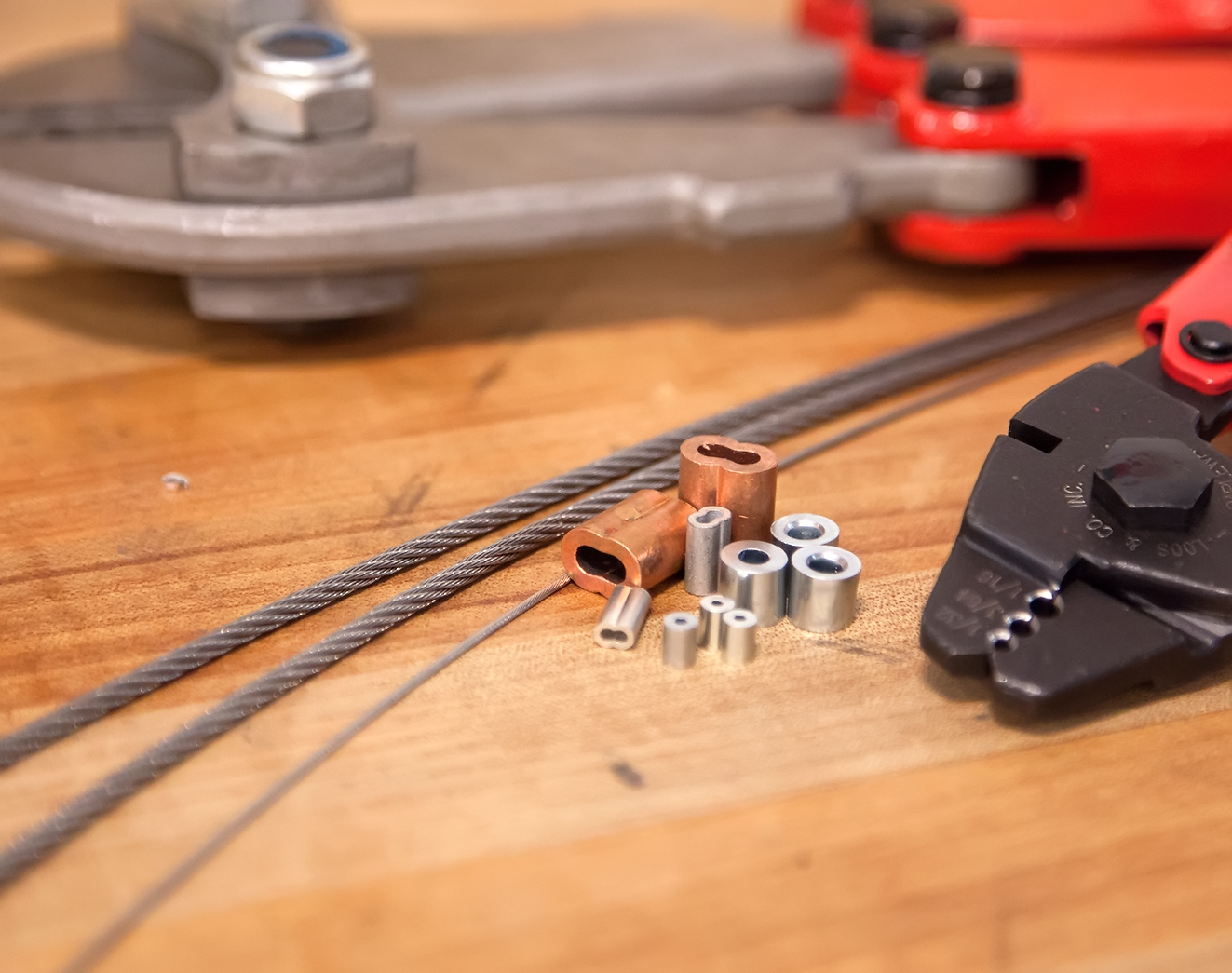

To swage wire yourself, you’ll want to start with a clean-cut end by using a set of bypass cutters. This will make threading the swage easier.

To swage wire yourself, you’ll want to start with a clean-cut end by using a set of bypass cutters. This will make threading the swage easier.

Make sure you’re using the correct tool and that you know how many crimps your swage requires – some only need one, while others need as many as four. Space your crimps out evenly across the swage to get the most strength out of them.

Make sure you’re using the correct tool and that you know how many crimps your swage requires – some only need one, while others need as many as four. Space your crimps out evenly across the swage to get the most strength out of them.

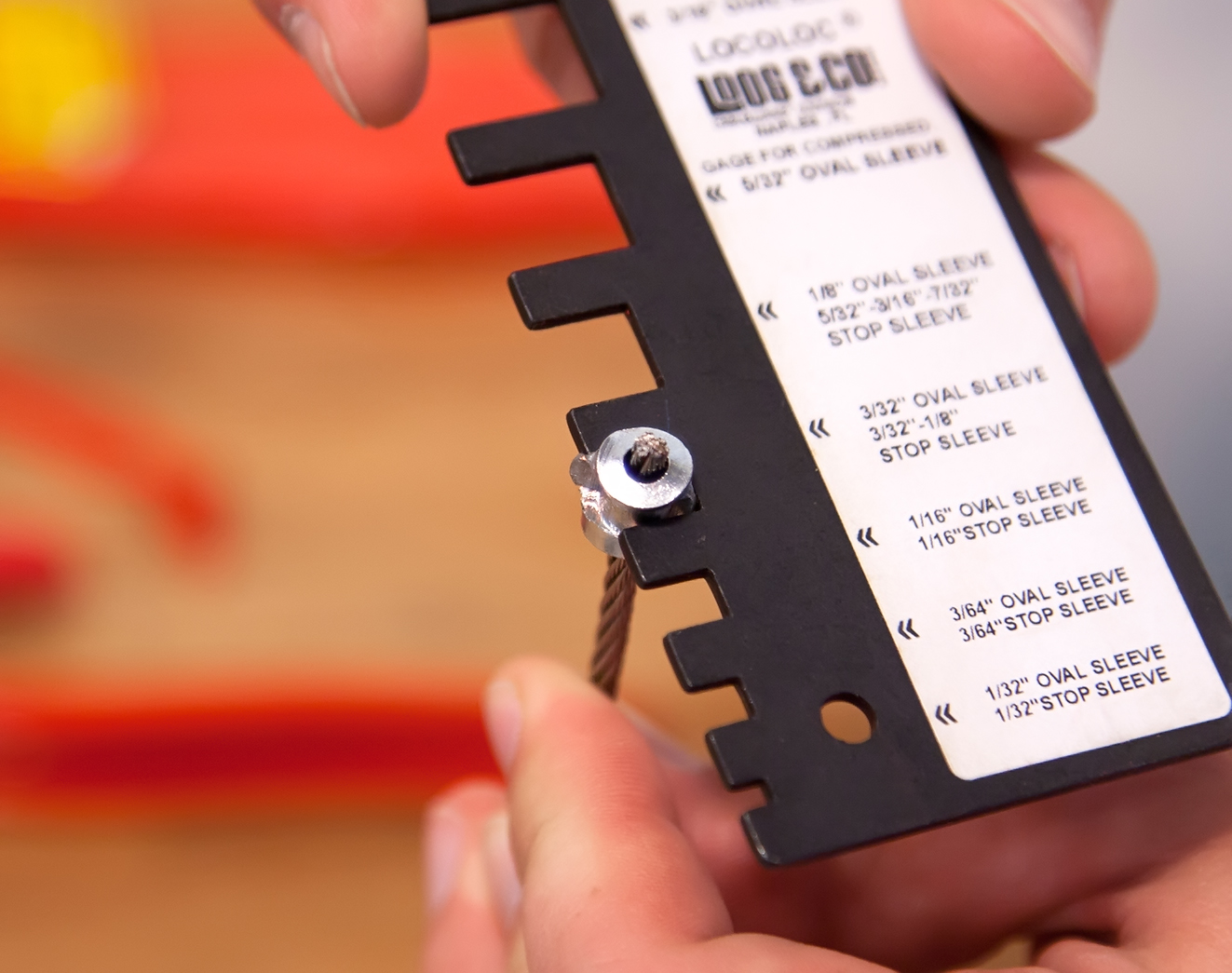

The crimping process works by crushing the swage and wire together, and will leave you with extra metal “flashing” that looks like small wings on the swage. This is normal and, as long as your swage fits in your gauge, won’t be a problem.

The crimping process works by crushing the swage and wire together, and will leave you with extra metal “flashing” that looks like small wings on the swage. This is normal and, as long as your swage fits in your gauge, won’t be a problem.

Once you complete your assembly, you’re ready to attach it to a surface using the appropriate anchor and start hanging your project. Our client solutions specialists can help you determine the best wire system for you and recommend the correct swage if you need one. If you choose a swage that can be applied by hand, we can also provide the necessary tools. Remember that, when it comes to wire, crimping is still in style.

Once you complete your assembly, you’re ready to attach it to a surface using the appropriate anchor and start hanging your project. Our client solutions specialists can help you determine the best wire system for you and recommend the correct swage if you need one. If you choose a swage that can be applied by hand, we can also provide the necessary tools. Remember that, when it comes to wire, crimping is still in style.